Metal Castings: proven methods shaping the future of industrial production

Wiki Article

A Deep Dive Into the Various Sorts Of Metal Casting and Their Utilizes

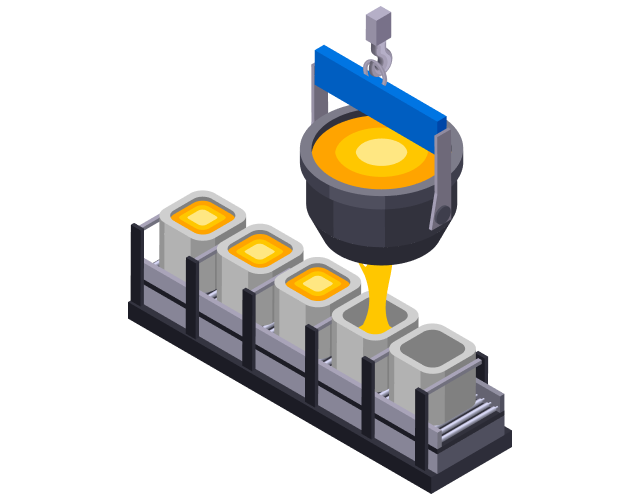

Metal Casting encompasses various techniques, each tailored for specific applications and requirements. From the cost-efficient sand casting technique to the accuracy of financial investment casting, each process has special advantages. Die casting stands apart in high-volume manufacturing scenarios, while shed foam spreading presents ingenious layout possibilities. Additionally, permanent mold and mildew casting is identified for its longevity. Comprehending these approaches opens a home window into their useful usages and implications in numerous industries. What exists under the surface area of these spreading methods?Sand Casting: A Affordable and versatile Approach

Numerous casting approaches exist, sand casting remains one of the most versatile and affordable strategies in the metalworking sector. This technique employs a mixture of sand and a binding representative to create mold and mildews, allowing for the manufacturing of parts in varied sizes and forms. Sand casting is especially advantageous for little to tool manufacturing runs, as it calls for very little upfront financial investment in tooling contrasted to various other casting strategies.The process starts with the creation of a mold and mildew, where liquified metal is put in to form the desired object as soon as cooled. Its versatility enables the use of various metals, consisting of steel, iron, and aluminum. In addition, sand spreading can suit complex geometries, making it appropriate for a series of applications, from automotive elements to complex imaginative pieces. In general, sand spreading's performance and adaptability solidify its importance in the production landscape.

Financial Investment Spreading: Accuracy and Information for Complex Shapes

Investment casting stands out as a method renowned for its capability to create extremely detailed and detailed elements. This procedure includes producing a wax pattern that is coated with a ceramic covering, which is after that heated up to get rid of the wax and harden the shell. The outcome is an exact mold that can record complicated geometric forms with exceptional precision.This spreading strategy is especially beneficial for generating get rid of thin walls, great features, and tight tolerances, making it optimal for markets such as aerospace, auto, and clinical gadgets. Investment spreading fits a selection of steels, including stainless steel, aluminum, and titanium, allowing makers to fulfill particular material needs.

The procedure reduces machining demands post-casting, which can enhance performance and decrease manufacturing costs. On the whole, financial investment casting is a recommended choice for applications where precision and detail are paramount.

Pass Away Casting: High-Volume Production With Excellent Surface Area Complete

Die spreading is an extremely effective manufacturing process that stands out in generating big volumes of metal components with phenomenal surface finishes. This method entails compeling liquified steel into a mold and mildew dental caries under high stress, permitting quick production cycles and uniformity in the completed items. Frequently made use of materials include magnesium, aluminum, and zinc, which provide superb mechanical buildings and corrosion resistance.

Die spreading is specifically advantageous for industries such as automobile, electronics, and durable goods, where accuracy and top quality are paramount. The procedure makes it possible for complex styles, minimizing the demand for extra machining and completing processes. Additionally, the smooth surface areas produced with die casting commonly require marginal post-processing, resulting in reduced total manufacturing costs. As a high-volume production method, die casting is optimal for manufacturers seeking effectiveness without jeopardizing on quality, making it a favored selection for plenty of applications throughout different sectors.

Lost Foam Spreading: Cutting-edge Approach for Intricate Designs

Lost foam spreading revolutionizes the production of complicated steel parts by making use of a distinct procedure that gets rid of the requirement for conventional molds. Rather of traditional mold-making, this approach utilizes a foam pattern that is coated with a refractory material. When the pattern is set, liquified steel is poured directly right into the mold, causing the foam to leave and evaporate behind a precise tooth cavity for the metal to fill up. This ingenious strategy enables elaborate designs and comprehensive attributes that may be testing to accomplish with various other casting approaches.Furthermore, shed foam spreading can lower waste and power intake, making it an environmentally friendly option. Industries such as aerospace and vehicle benefit substantially from this strategy, as it sustains the production of light-weight parts Aluminum Castings with complicated geometries. Overall, shed foam spreading stands apart for its capability to provide top notch, personalized steel parts successfully.

Irreversible Mold Casting: Resilience and Consistency in Metal Parts

Permanent mold and mildew casting is a highly efficient technique for producing sturdy and constant steel components, leveraging multiple-use mold and mildews that are usually made from metals such as iron or steel. This casting process entails putting molten steel into these molds, which are preheated to enhance product high quality and minimize problems. Making use of reusable molds not only decreases waste but also enables greater manufacturing prices, making it economically useful for makers.The resulting elements exhibit outstanding dimensional accuracy and surface coating, making them suitable for applications in automotive, aerospace, and industrial equipment. Furthermore, long-term mold casting can suit a variety of alloys, further increasing its adaptability. The sturdiness of the cast components is enhanced as a result of the controlled cooling rates that promote finer grain frameworks. On the whole, this casting strategy stands out for its capability to generate top quality metal components that satisfy extensive efficiency standards, ensuring reliability in requiring atmospheres.

Often Asked Inquiries

What Materials Can Be Used in Various Metal Casting Procedures?

Various products can be used in Metal Casting processes, consisting of aluminum, zinc, bronze, and iron. Each material offers unique residential or commercial properties, influencing the casting approach's efficiency, stamina, and viability for various applications in manufacturing.

How Do Casting Approaches Influence the Mechanical Features of Metals?

Casting approaches significantly influence the mechanical residential properties of metals, influencing factors like firmness, toughness, and ductility. Variants in cooling down prices and mold products can result in different microstructures, inevitably impacting the performance of the last item.What Are the Environmental Effects of Steel Casting Procedures?

Metal Casting procedures can lead to air and water pollution, source depletion, and substantial power intake (Metal Castings). In addition, the generation of waste products and greenhouse gas emissions greatly influences the setting and contributes to environment changeExactly how Do You Pick the Right Casting Technique for a Job?

Picking the right casting approach entails evaluating project demands, material buildings, complexity, and production quantity. Factors like price efficiency, surface quality, and lead time likewise play important duties in establishing the most ideal approach.What Security Safety Measures Should Be Taken Throughout Metal Casting Procedures?

During Metal Casting procedures, safety preventative measures include putting on protective gear, making sure correct ventilation, carrying out equipment examinations, preserving a tidy work area, and having emergency procedures in position to deal with possible risks like burns or toxic fumes.From the cost-effective sand spreading technique to the accuracy of financial investment casting, each process has distinct benefits. Pass away casting is a very efficient production procedure that excels in generating huge volumes of steel components with phenomenal surface coatings. Lost foam spreading reinvents the production of complex metal parts by utilizing an unique process that gets rid of the demand for traditional mold and mildews (Wisconsin Aluminum Foundry). Permanent mold and mildew casting is a very effective method for creating durable and consistent metal components, leveraging recyclable mold and mildews that are commonly made from steels such as iron or steel. Various materials can be utilized in Metal Casting processes, consisting of light weight aluminum, bronze, zinc, and iron

Report this wiki page